- 15 March 2023

- 5759 defa okundu.

Feldballe School

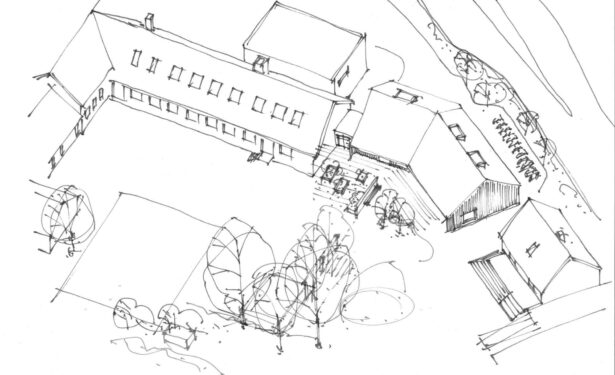

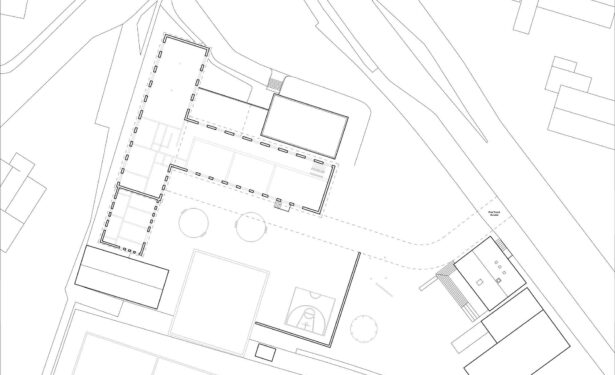

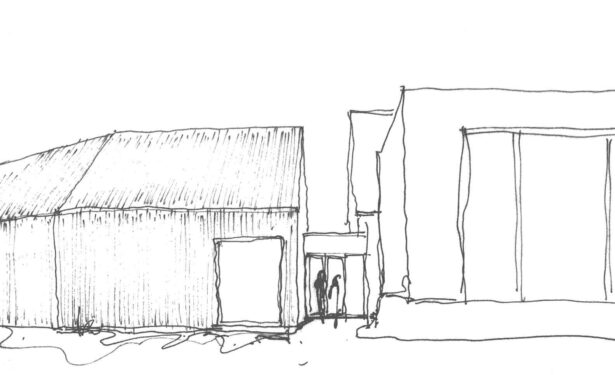

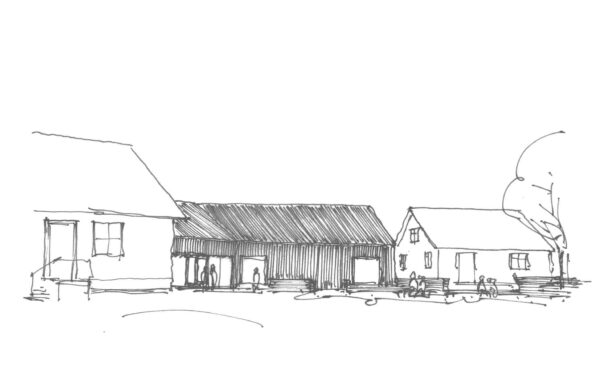

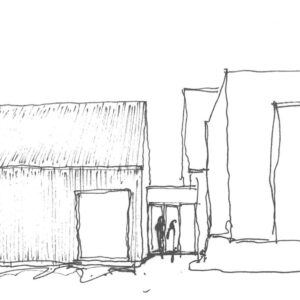

Designed for the climate crisis generation, the Danish school extension built of wood and straw is a scalable solution for carbon sequestering, giving the world a lesson in eco-innovation.

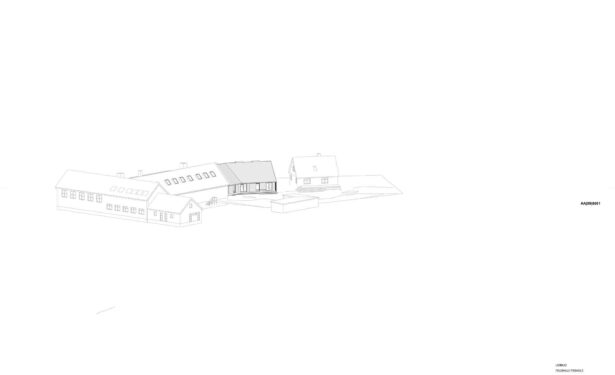

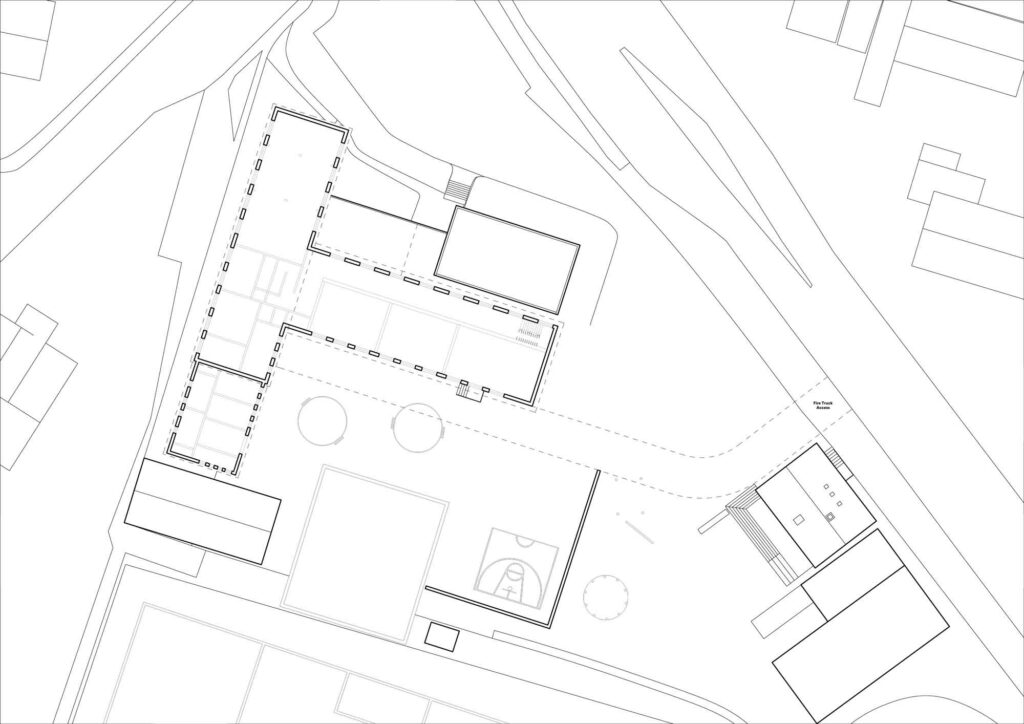

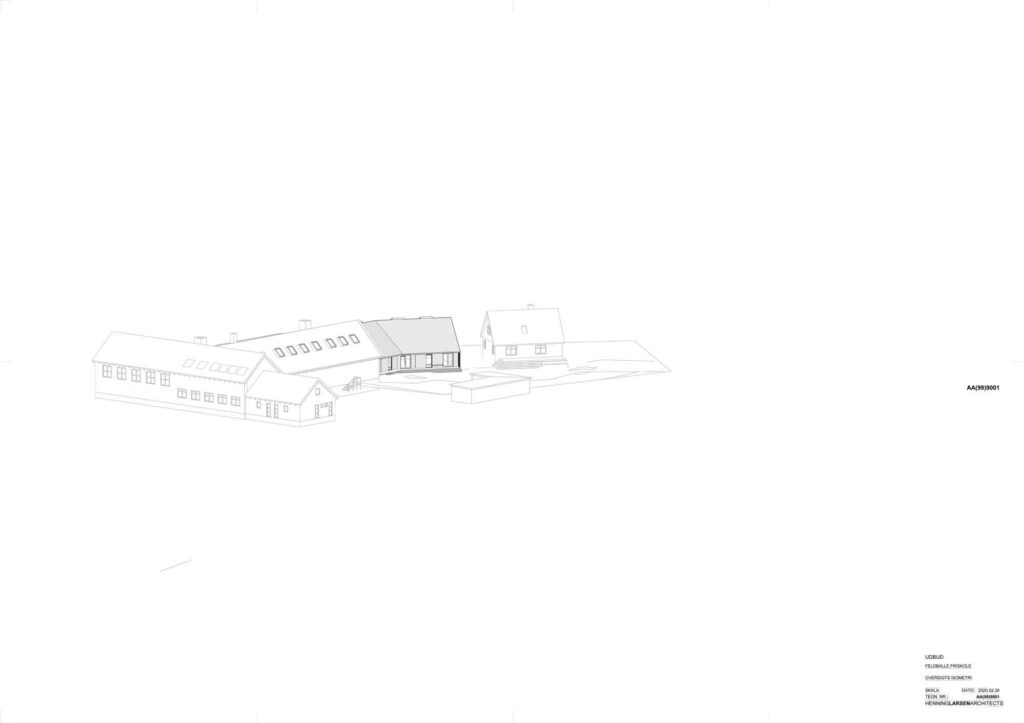

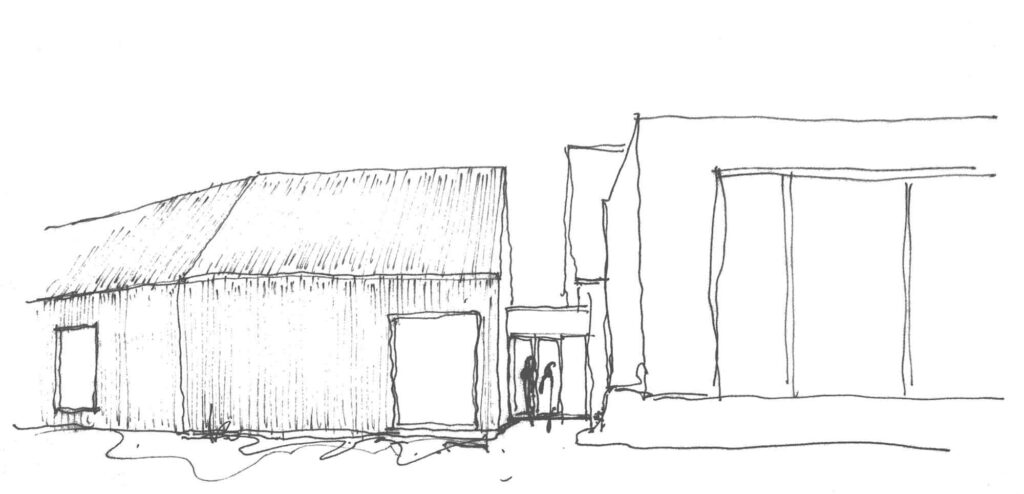

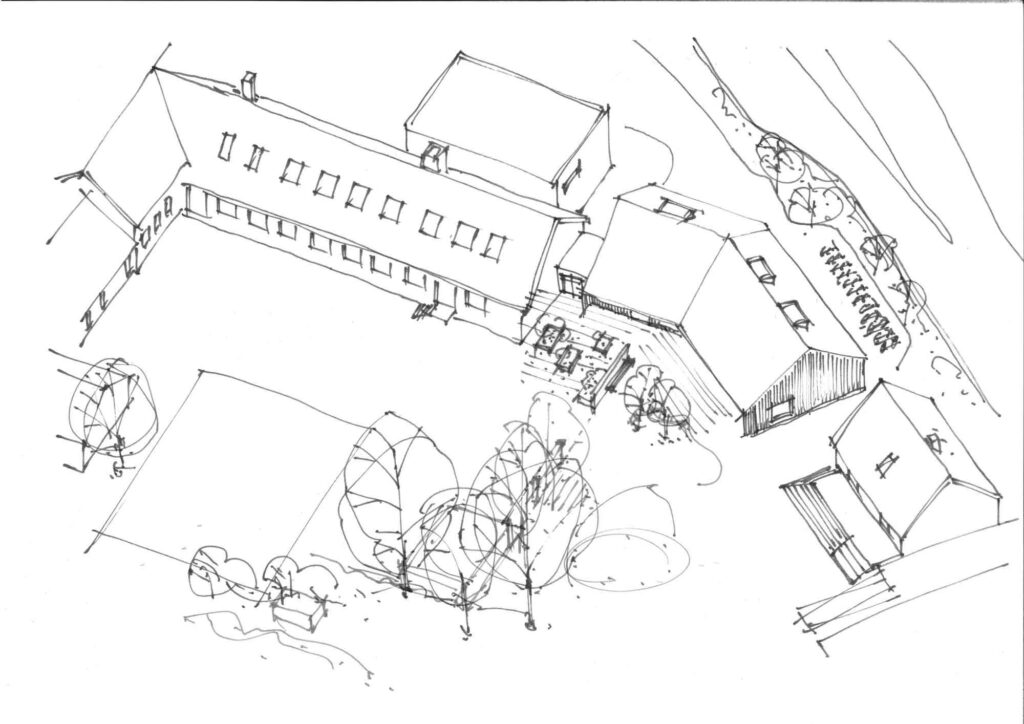

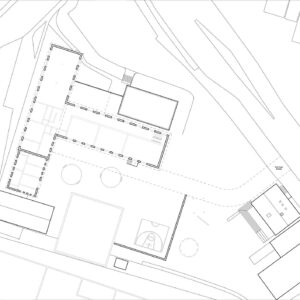

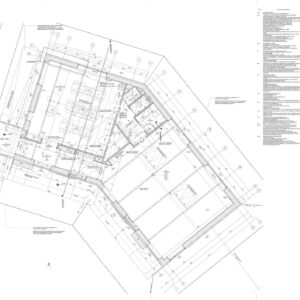

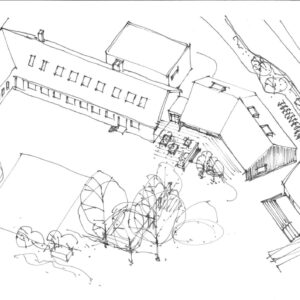

Driven by the commitment to design a building that captures more carbon than it emits, the 250 m2 extension of Feldballe School in Rønde, Denmark, is Henning Larsen’s most ambitious project to date. Built for science classes for a generation that will come of age with the weight of the climate crisis, the architecture practice implemented an uncompromising material strategy; rethinking the conventional building blocks.

Embodying immense potential without compromising on function, atmosphere and architectural expression, the school extension is built almost entirely of bio-based materials, viable alternatives to concrete, brick and steel, and crucially, materials that sequester rather than emit CO2, are totally free of toxic chemicals, fire-safe, and offer both efficient insulation and a great indoor climate.

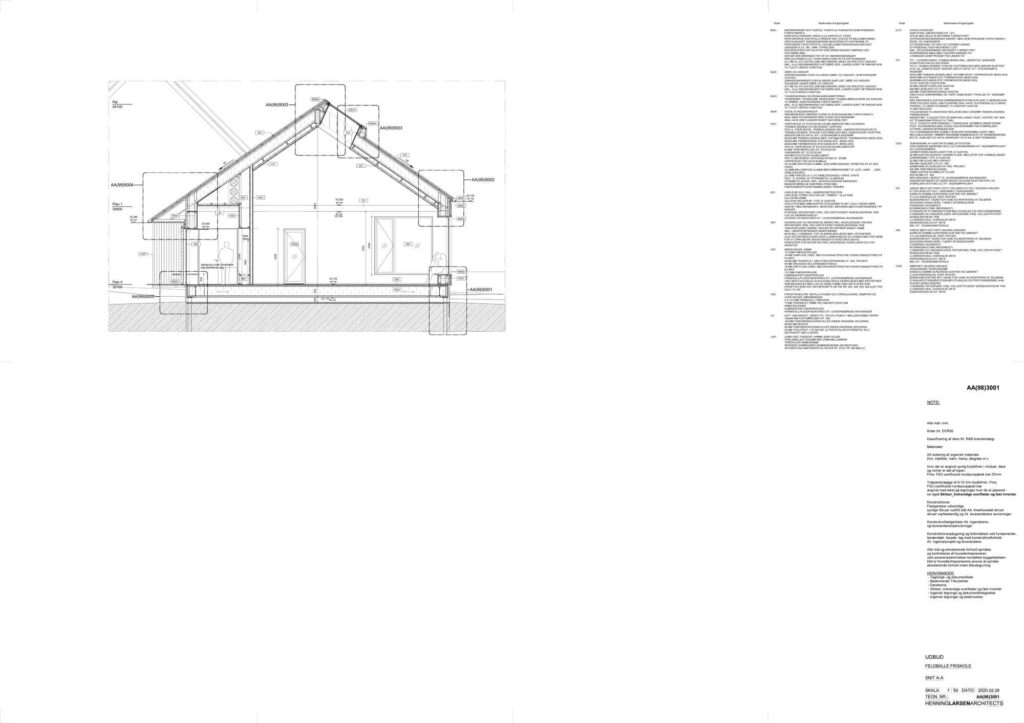

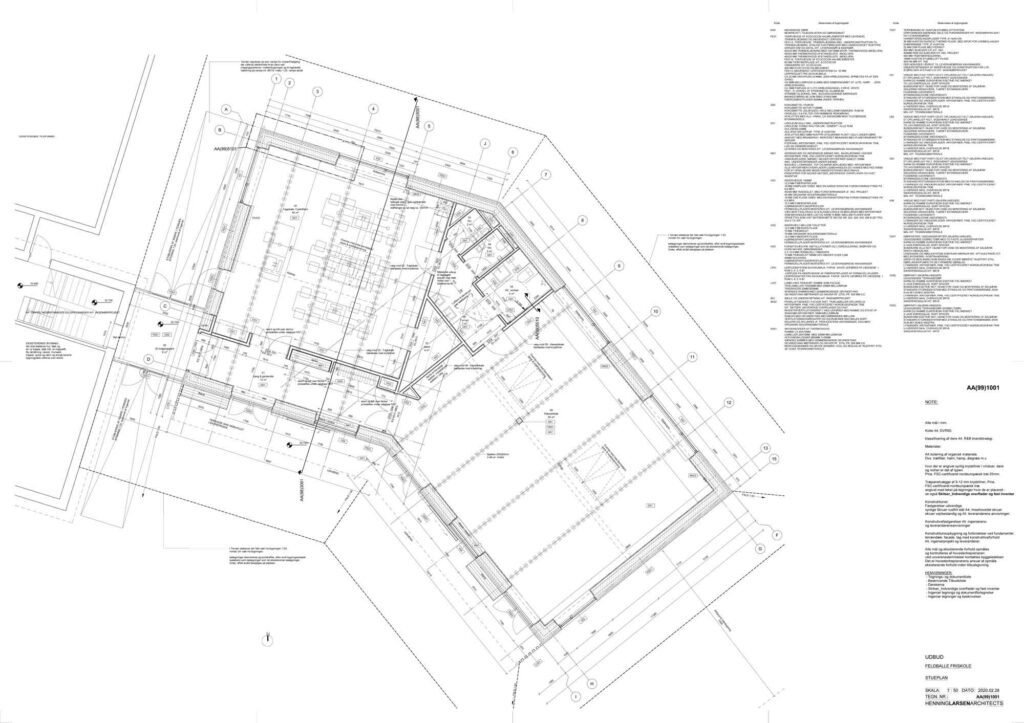

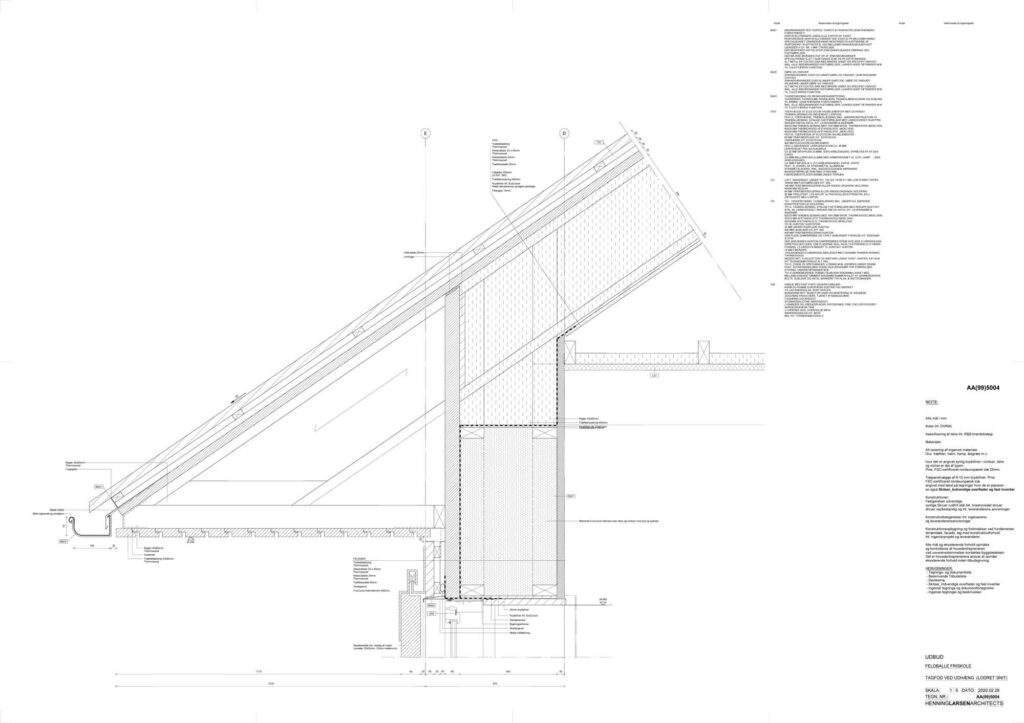

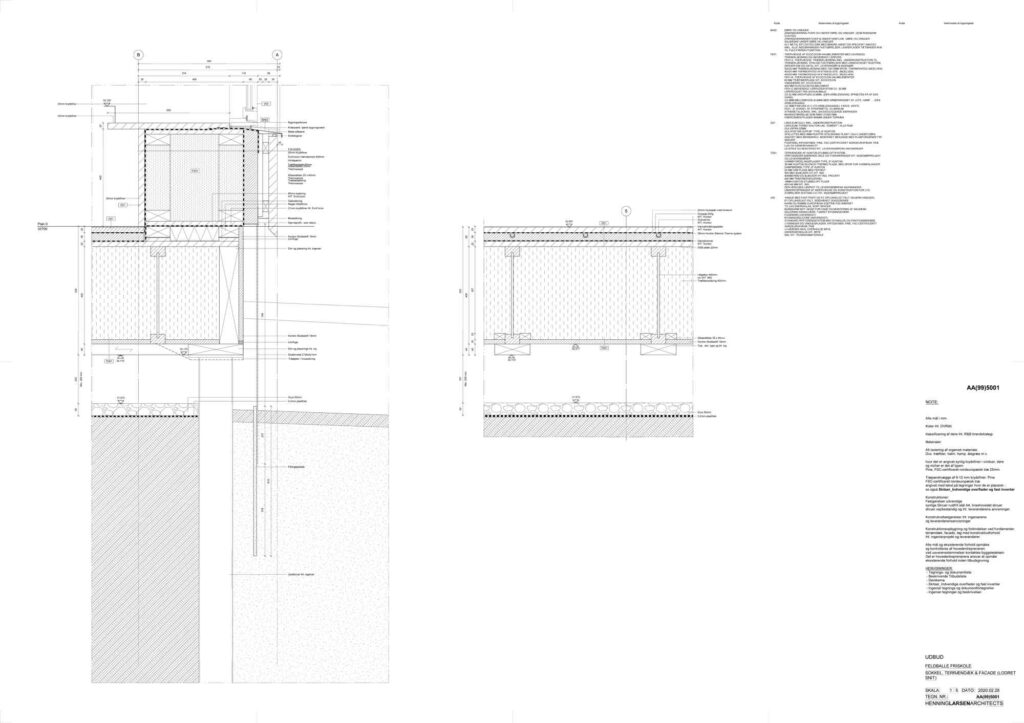

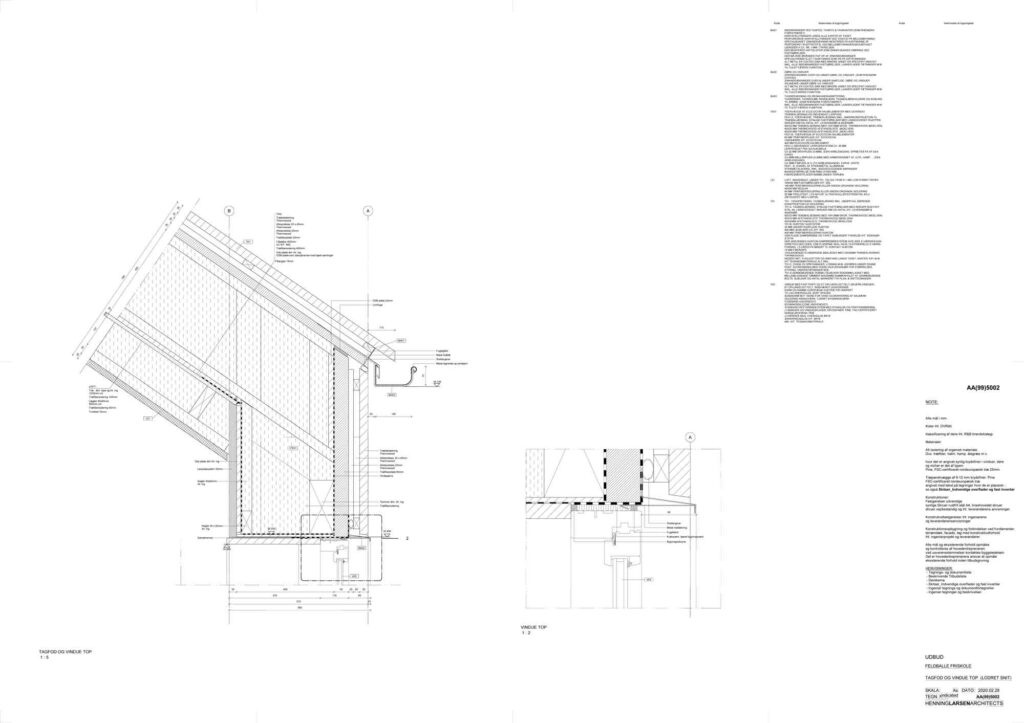

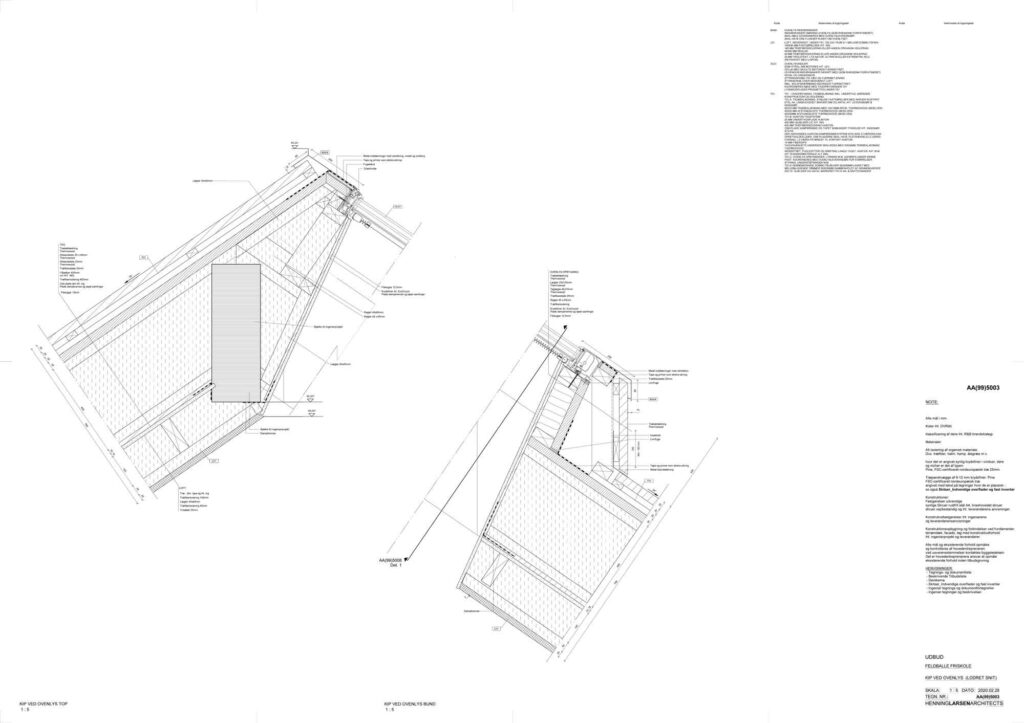

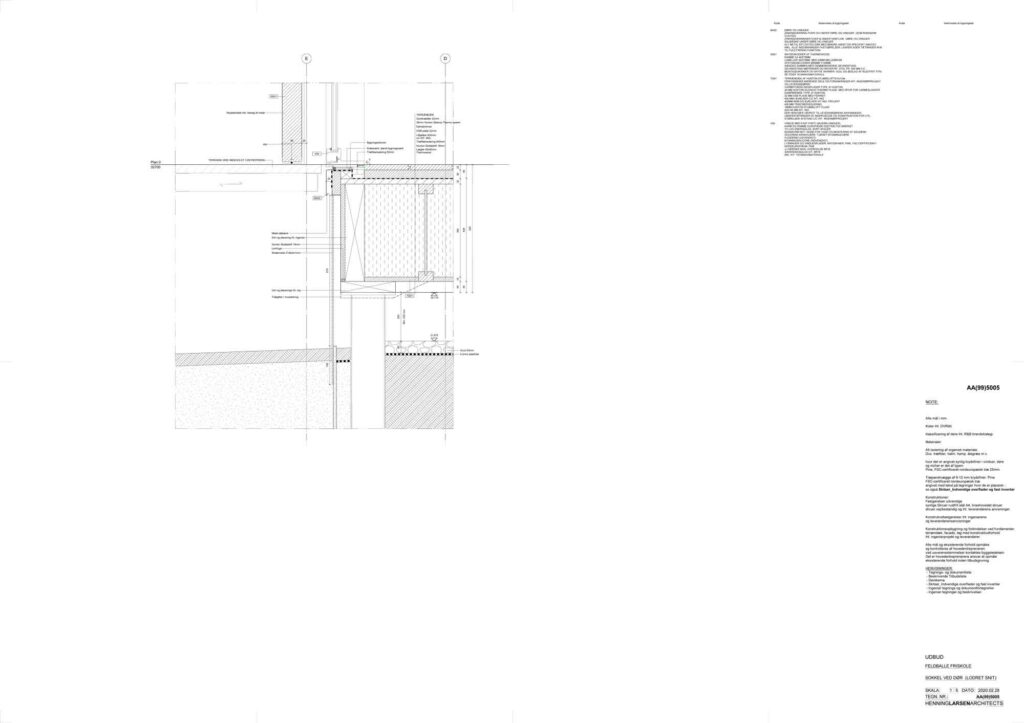

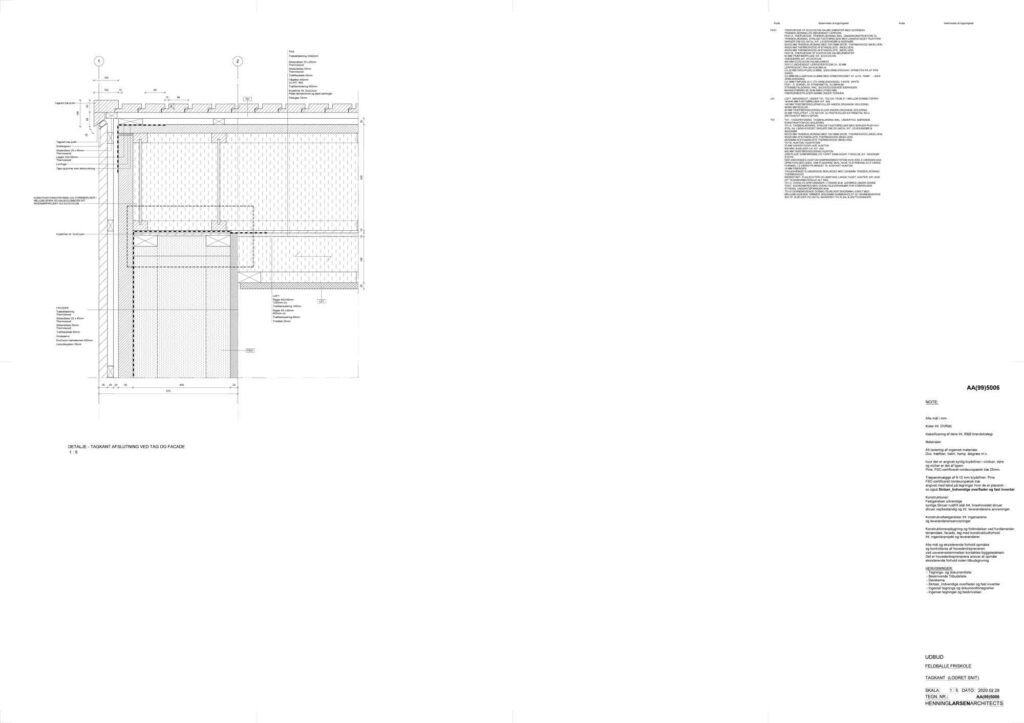

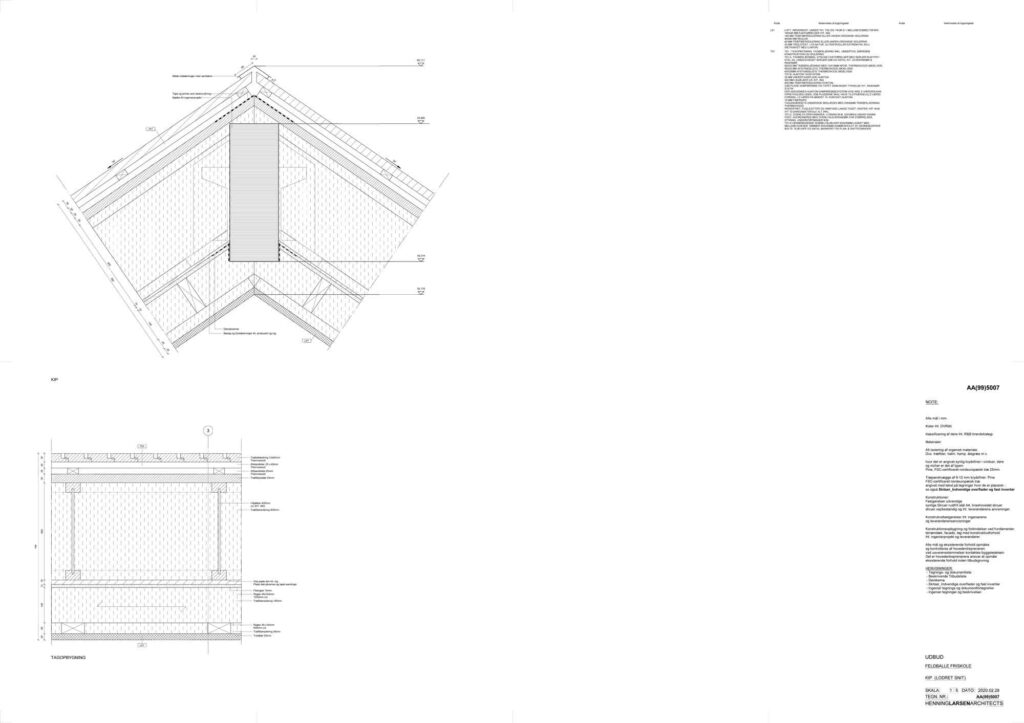

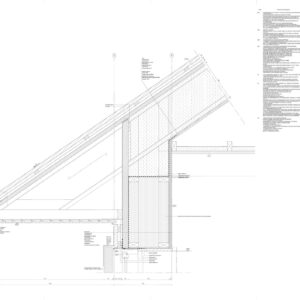

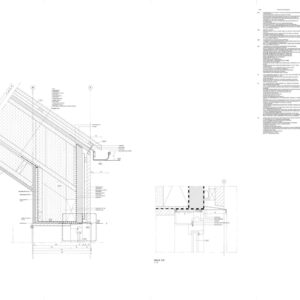

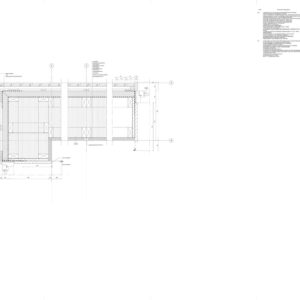

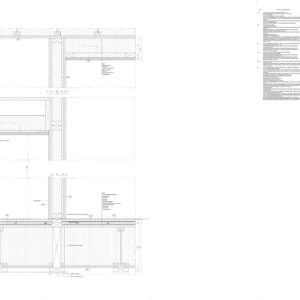

With support from the Danish philanthropic organization, Realdania, and in partnership with EcoCocon, the final design solution is a structure made of a pioneering panel system of compressed straw, a roof made solely of timber, and a ventilation system made of eelgrass – a common seaweed along seashores in the majority of the Northern Hemisphere.

Small in scale but big in impact

The project has redefined the standards for sustainable construction, examining the entire life cycle of a building. Part of eco-community Friland, the school’s goal of preparing a future generation of thinkers, leaders, and community members committed to creating a more sustainable world was a catalyst for the design ambition.

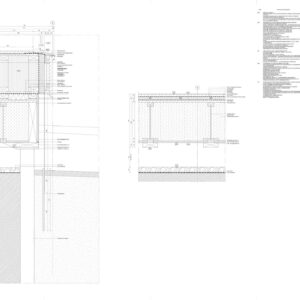

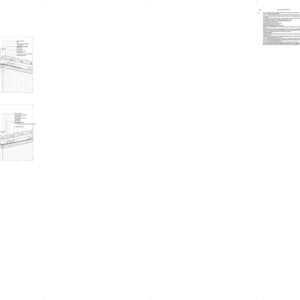

The design team created a framework for sustainable design that doesn’t exceed planetary boundaries, comprising five ambitious principles: incorporate sustainably sourced, renewable, bio-based materials to sequester carbon; use already produced local materials to save resources and energy; employ materials that are free of toxic chemicals, minimizing off-gassing and ensuring clean production and processing procedures; lower operational energy consumption by ensuring a healthy indoor climate, fostering an environment that balances daylight with passive ventilation; design for disassembly, enabling the reuse of building components in the future.

Operationalizing these principles, the design team successfully surpassed the targets, arriving at a footprint of 6kg of CO2e per m2 per year, over a lifespan of 50 years – per Danish standards. Provided the space remains used and respected by the school community beyond the next few decades, the footprint is reduced further to -3kg of CO2e per m2, per year*.

“The latest IPCC report gives us an extremely small window of opportunity for keeping global temperature increase to a maximum of 1.5 degrees Celsius, just a decade. We know that we cannot wait for policymakers to push the green agenda, we must face the weight of our design decisions headfirst, altering our practices, bettering ourselves, and pushing our industry.

Thinking critically about the production line in its entirety we have shown that quality and function are not compromised by using fewer resources. Straw is a fast-growing renewable resource and a byproduct of agriculture; a great alternative to producing new materials. For this project, the straw was sourced from as nearby as neighboring fields,” says Jakob Strømann, Director of Sustainability and Innovation, Henning Larsen

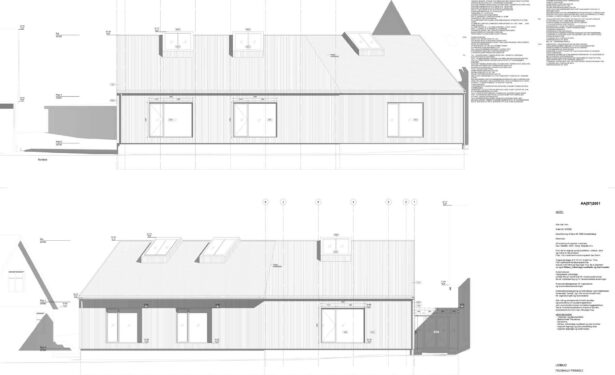

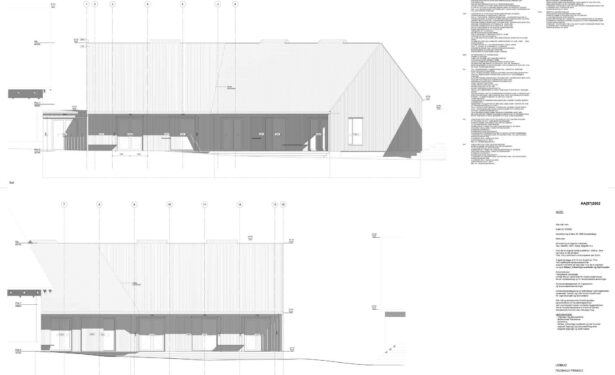

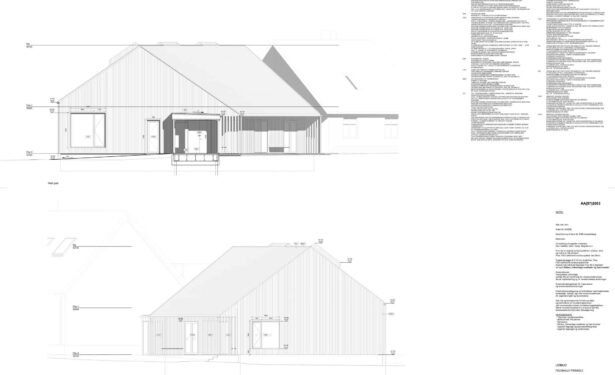

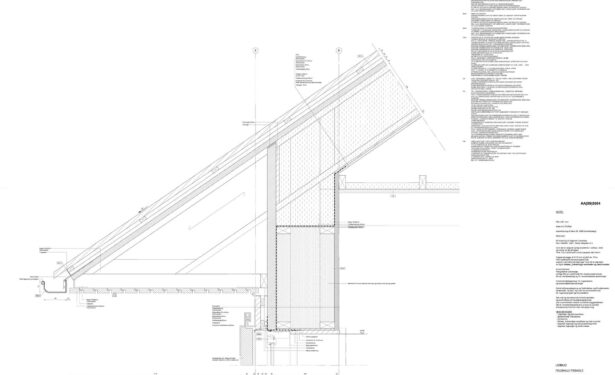

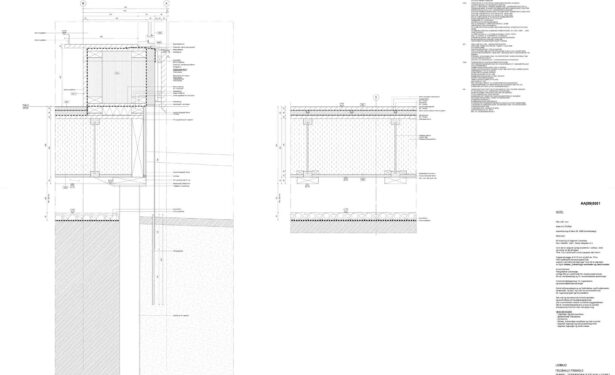

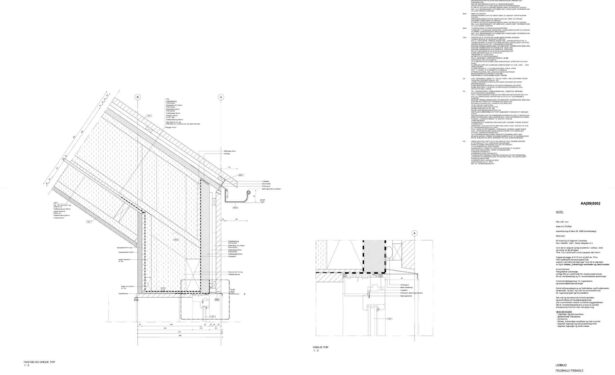

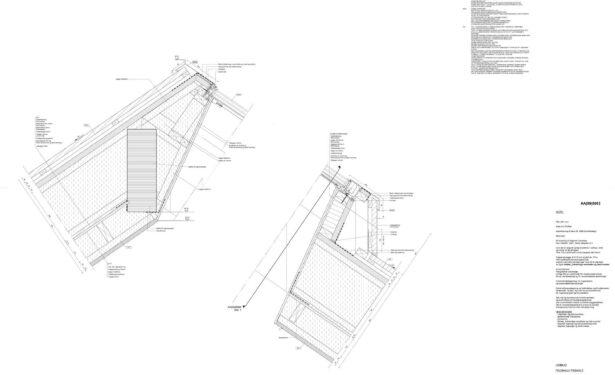

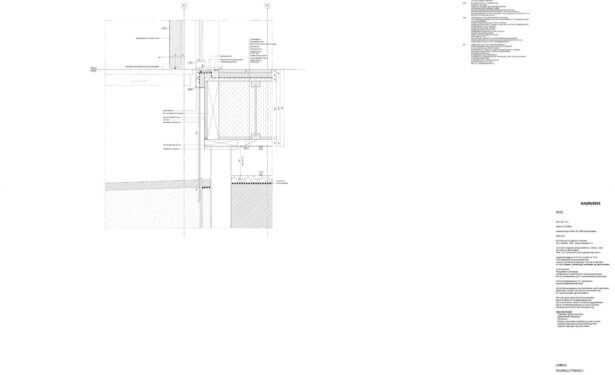

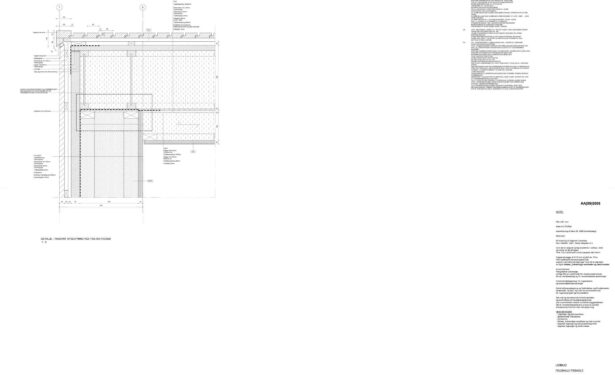

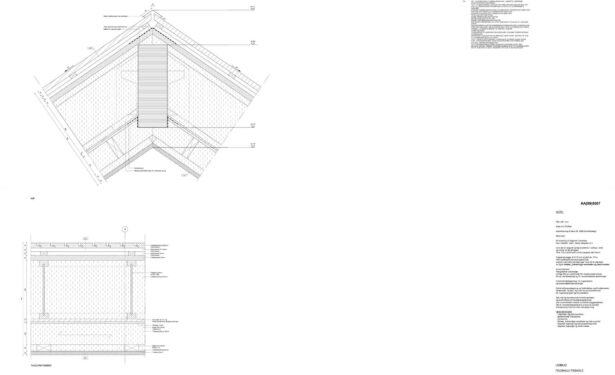

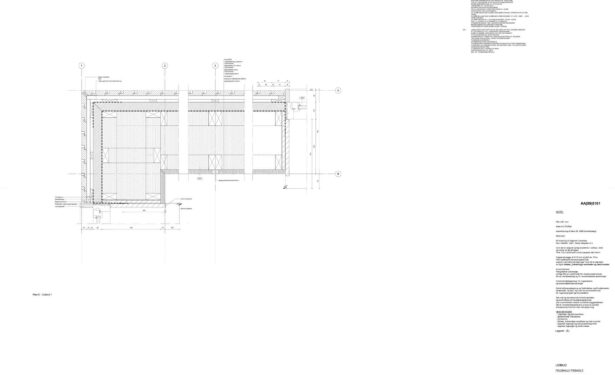

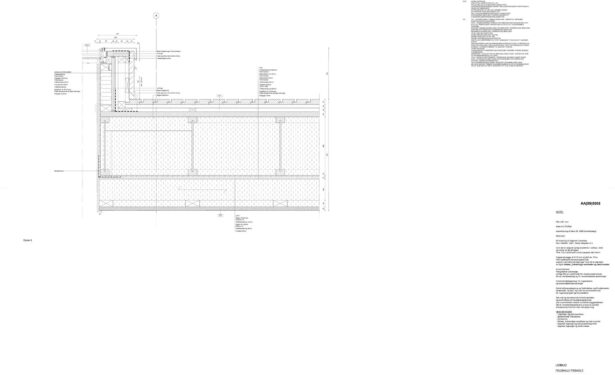

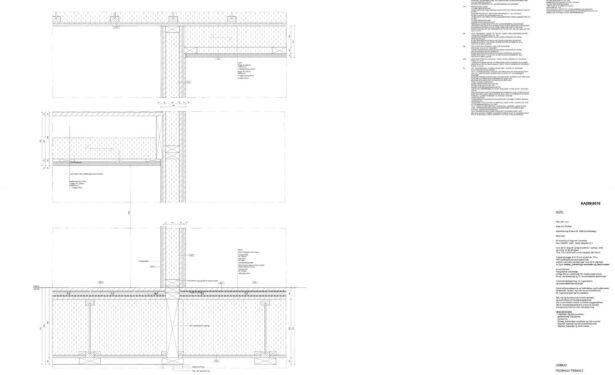

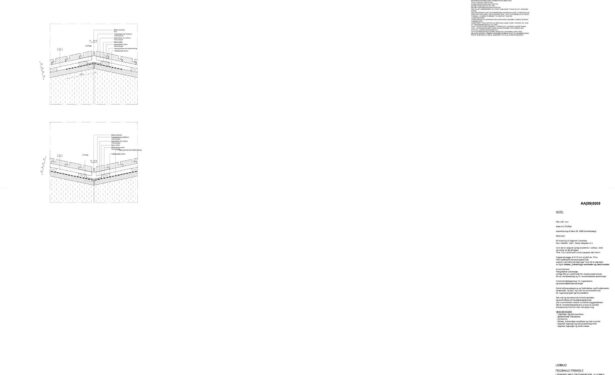

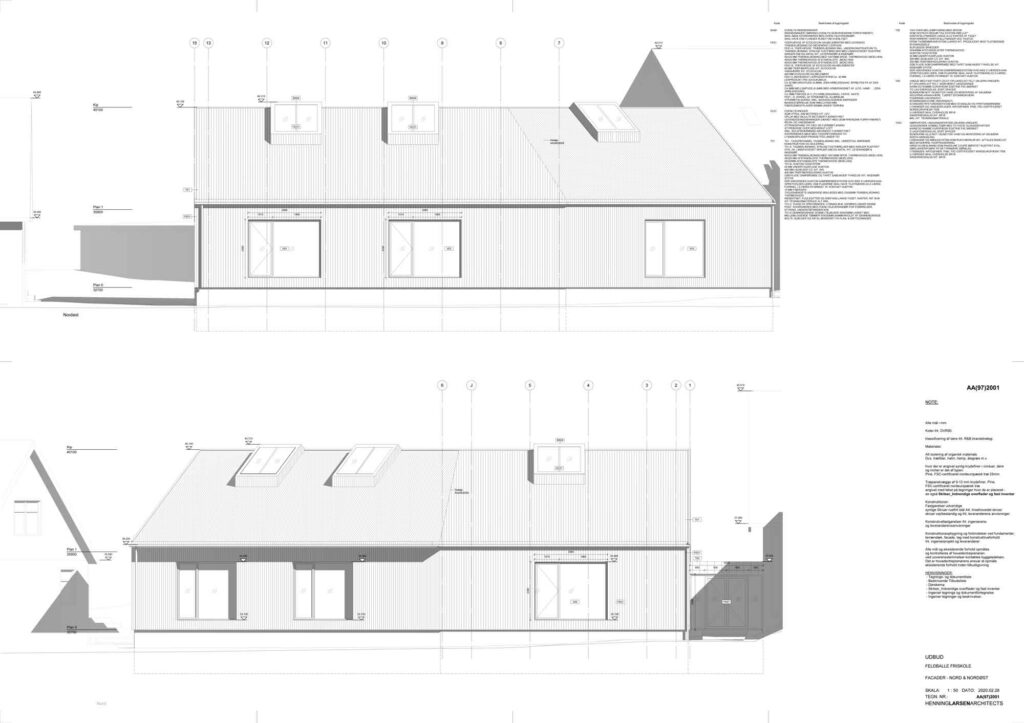

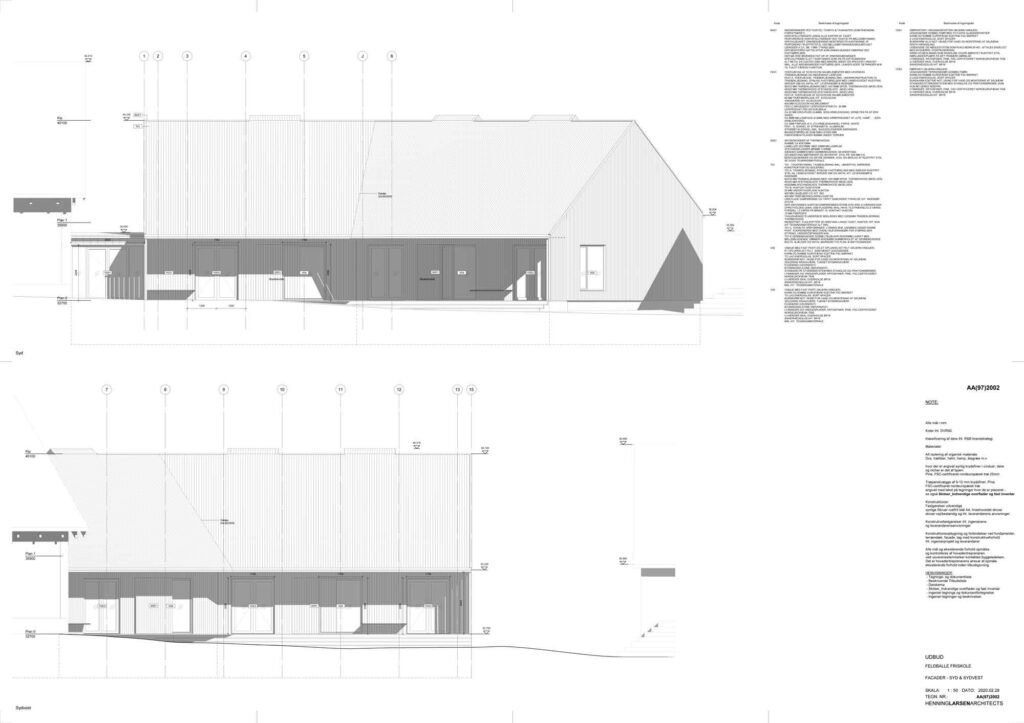

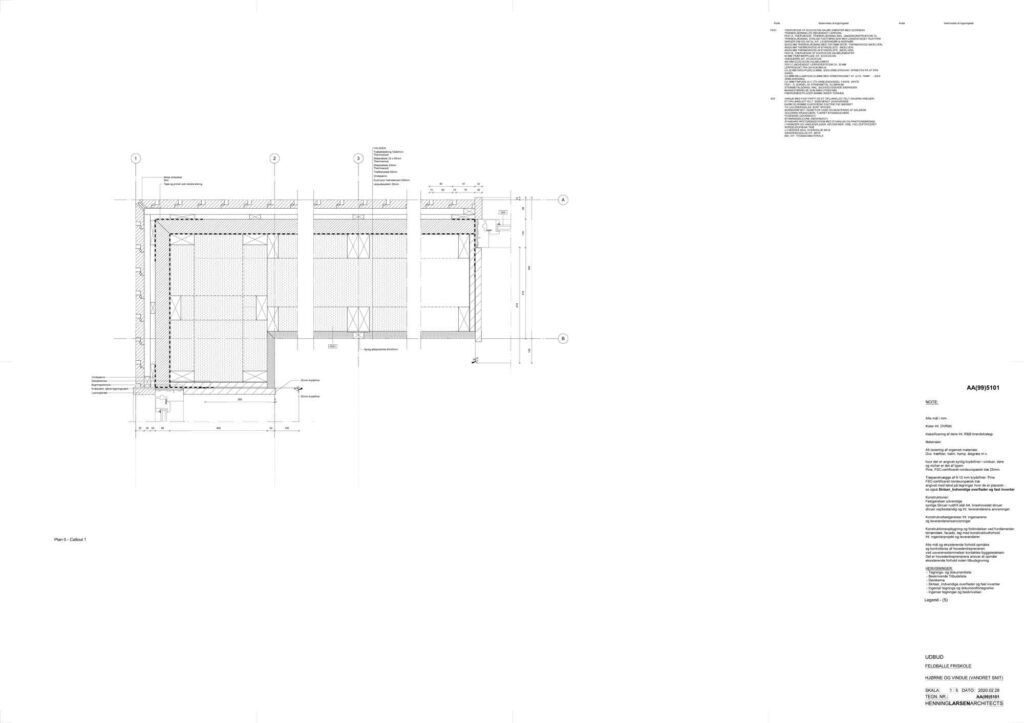

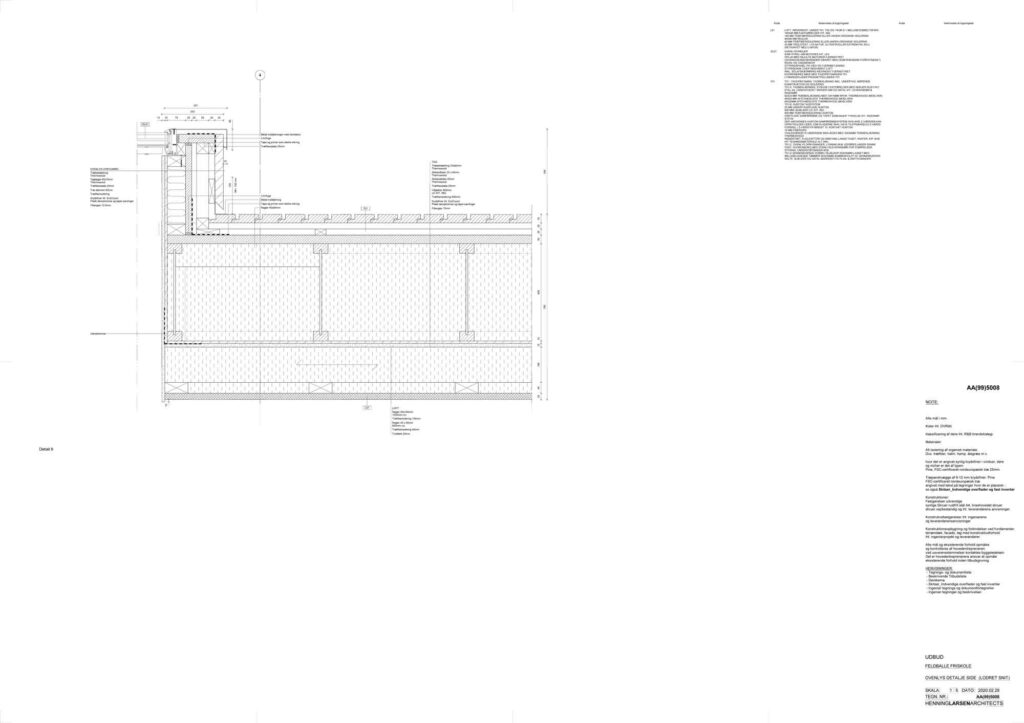

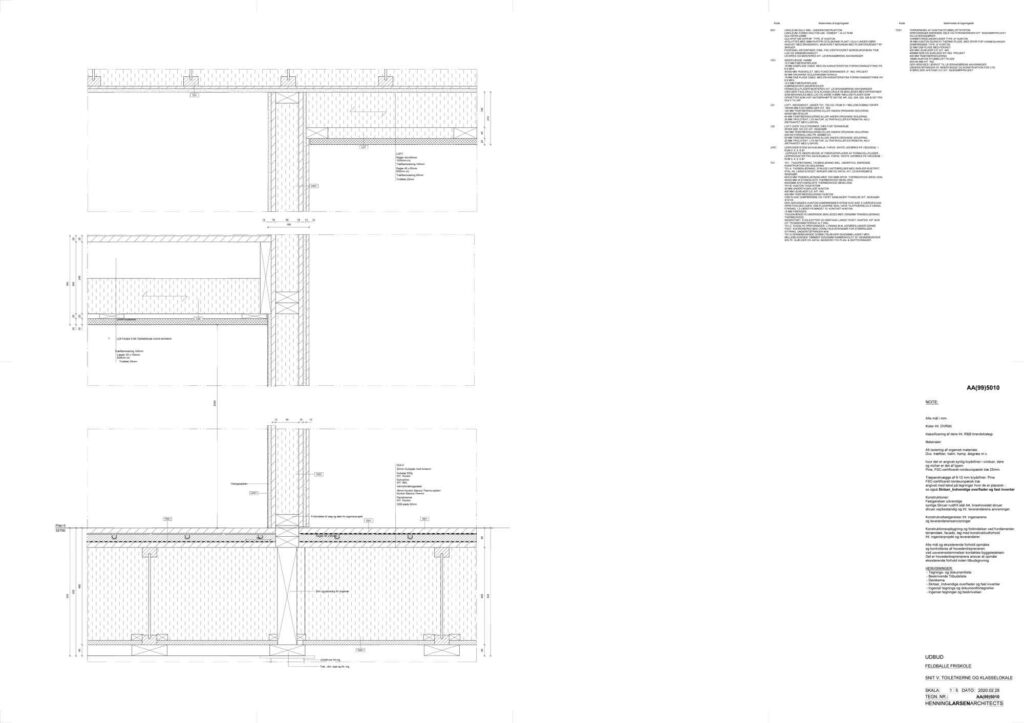

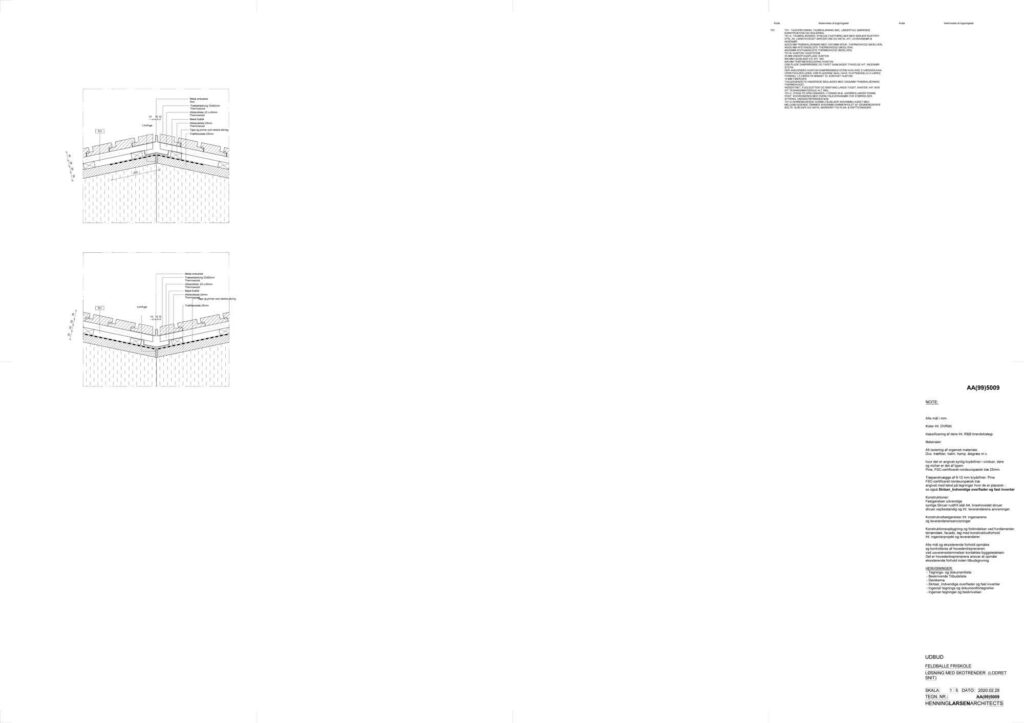

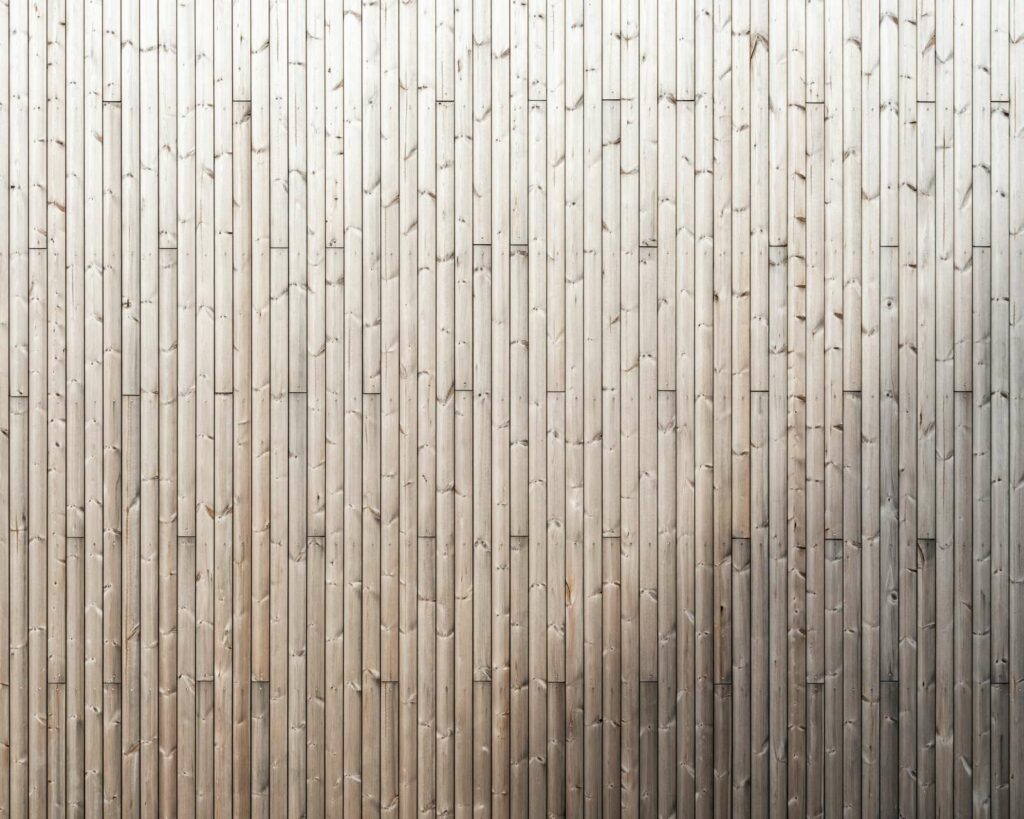

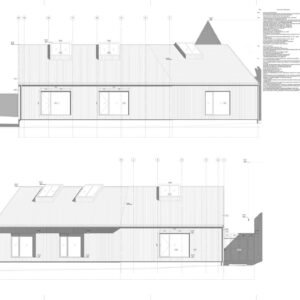

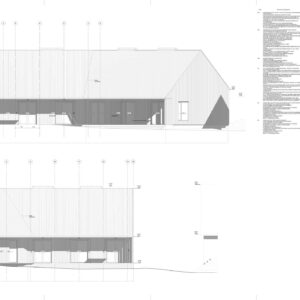

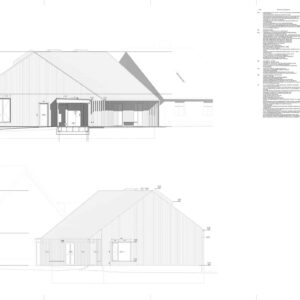

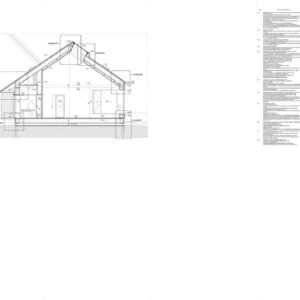

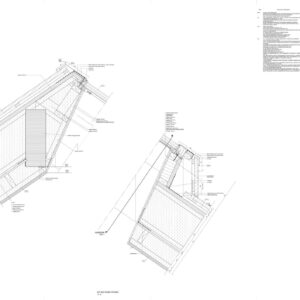

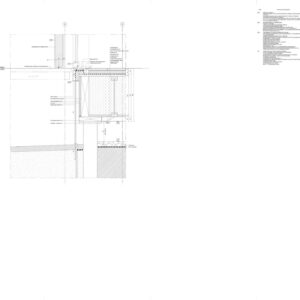

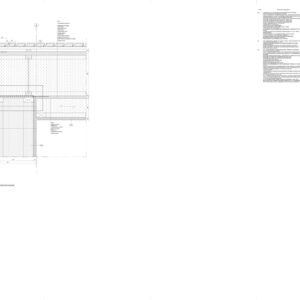

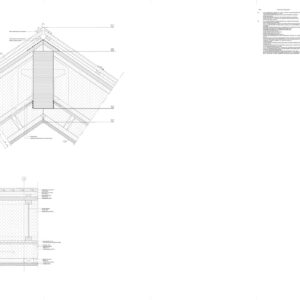

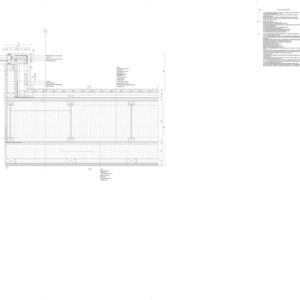

The integrated panel system of compressed straw in wooden cassettes was produced by partners EcoCocon with the utmost precision, forming a construction system that is adaptable and applicable in a vast range of building typologies. The roof is made entirely of certified locally produced timber, and untreated plywood makes up the surfaces of both the inner walls and the built-in furniture. The natural materials lend the extension a warm, welcoming expression, and because there is no need for large ventilation ducts or suspended ceilings, the rooms are spacious and high-ceilinged.

The integrated panel system of compressed straw in wooden cassettes was produced by partners EcoCocon with the utmost precision, forming a construction system that is adaptable and applicable in a vast range of building typologies. The roof is made entirely of certified locally produced timber, and untreated plywood makes up the surfaces of both the inner walls and the built-in furniture. The natural materials lend the extension a warm, welcoming expression, and because there is no need for large ventilation ducts or suspended ceilings, the rooms are spacious and high-ceilinged.

Natural and passive ventilation systems eliminate energy consumption on a daily operational level, further supported by solar panels on the roof. The permeable characteristics of straw allow humidity to escape, and the interior walls consist of clay plaster supporting its diffusion qualities. Air filters of eelgrass allow natural ventilation, automatically controlled by monitoring air quality and temperature.

The entire structure is designed for easy disassembly and reuse, prioritizing circularity and waste management, offering flexibility, ease of repair, and making it possible to reinstall or recycle its parts in the future.

“With Feldballe School as a testing ground for integrating novel solutions, we are already in the process of scaling this model up for a 13,000 m2 project.

With an agenda that extends far beyond the site’s 2700 square feet, our work on Feldballe School acts as a guide, not only for ourselves but for others in confronting our industry’s carbon emissions across the value chain. The result of this is a new aesthetic language that goes far beyond simply pleasing the eye or being grand in scale, it is lined with social and environmental responsibility, and more importantly, an impactful offering to both,” says Jakob Strømann, Director of Sustainability and Innovation, Henning Larsen